What do you mean my heat exchanger is too big?

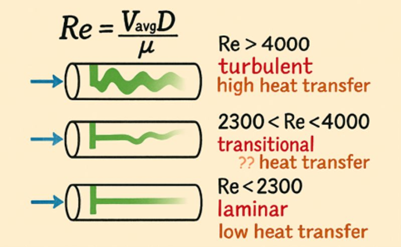

I’ve never met a heat exchanger that was too small to start with. But can they be too big? When you are looking for precise control with large turndown, then definitely. Ever had trouble controlling your heat exchanger at low flow or load? The culprit could be the flow regime, and our old friend the Reynolds number. Reynolds number is a dimensionless constant used to predict fluid flow regimes which is widely used in fluid pressure loss calculations. But it also has an impact on heat transfer. At Engineered Efficiency, we pay close attention to this factor when designing heat transfer systems.

Let’s start with why heat exchangers are often oversized. Say you are designing a process system for 20 tonnes per hour. You will probably make an allowance and add 10%. Hand that to the project team, who add another 10% to be safe when they write the specification. The heat exchanger manufacturer gets the RFQ, adds a bit of fat to make sure they don’t come in undersized, and adds a fouling factor as well. Nett result, the shiny new exchanger is 40-50% oversized… for your 20tonne/hour duty (which may have been optimistic anyway). So even more oversized for any reduced duty.

If a heat exchanger is oversized and cooling water flow (for instance) is heavily restricted to cope with a low heat load, it can enter a laminar flow regime where heat transfer can drop dramatically. Laminar flow moves in smooth layers, which reduces turbulence and limits mixing, meaning less heat is removed than anticipated. Turbulent flow, by contrast, enhances heat transfer.

This means at low duty, a cycle can result. The control valve restricts cooling or heating flow to achieve the target outlet temperature. But this pushes the flow into laminar regime, with a significant reduction in heat transfer rate and a step-change in the product outlet temperature. In response, the control valve opens to allow more flow, which transitions back to a turbulent regime, significantly increasing heat transfer rate with a step-change back the other way, and so on.

There are ways to set up heat transfer systems to overcome these issues. Understanding Reynolds number and the flow on effects within your heat transfer system are important where you are expecting large turn-downs in duty. Small miscalculations can lead to inconsistent outlet temperatures or loss of control completely— something every engineer wants to avoid.